We will replace the structural components in our agrivoltaic systems with renewable materials, thus using organic structures instead of steel in construction.

Materials such as flax, carbon, wood fiber or other renewable resources are processed to produce the substructure in such a way that they are particularly strong. Nature has inspired technology here, as the new structures resemble trees more than buildings and blend excellently into the landscape. Here, you will learn about the advantages this construction method has for agrivoltaics and agriculture in general. Do you want to know what these installations will look like? Here you can find the images.

Together with our technology partner FibR GmbH, we have tested innovative lightweight construction methods with organic materials and plan to go into mass production in 2026. The goal is to fundamentally revolutionize the solar industry, making it more sustainable, cost-effective, and European.

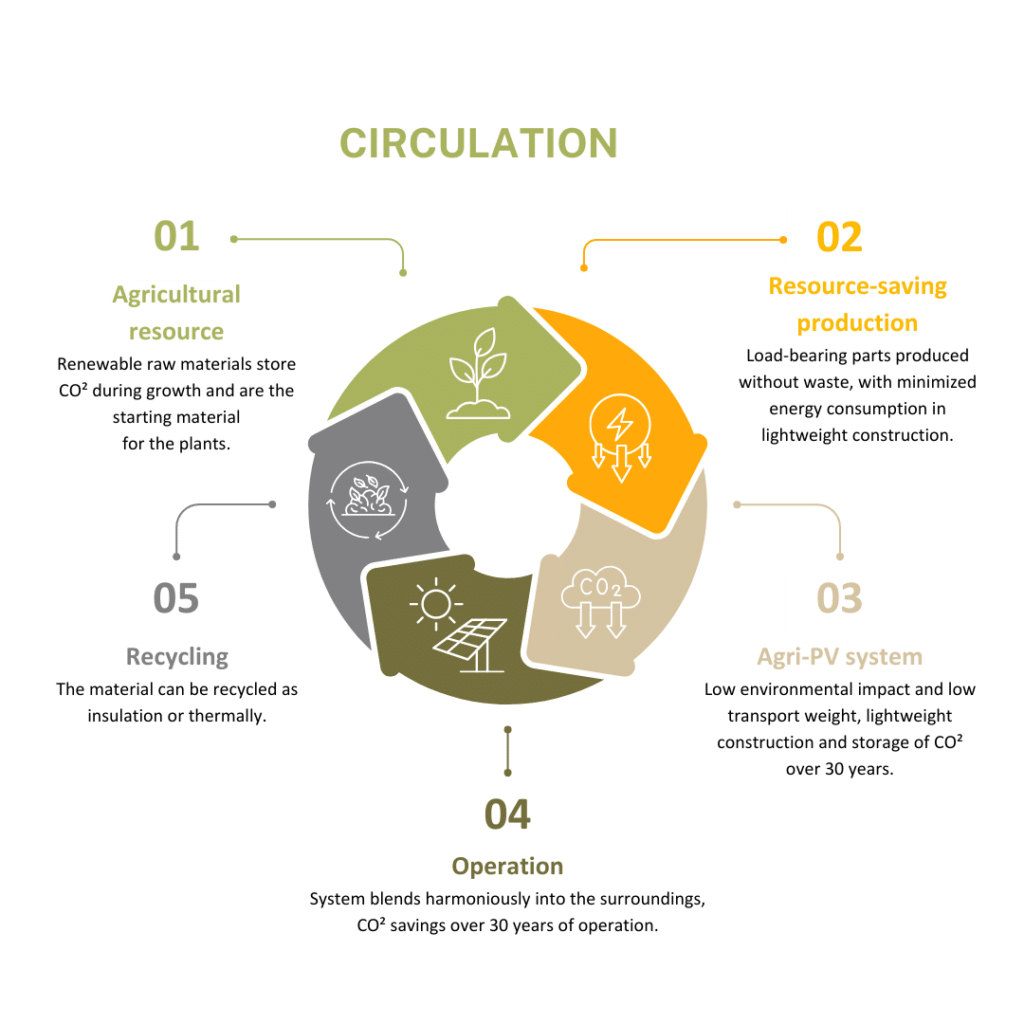

Renewable raw materials from agriculture are the starting material for the systems; they are used in material-saving lightweight construction for the construction of the Agri-PV systems. The production, construction and operation of the system requires less energy and therefore has a lower environmental impact, and recycling after 30 years leads back into the natural cycle.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The new materials make much larger spans over the fields possible. This enables us to plan new designs for our products that are even better suited to agricultural cultivation. Moreover, they blend organically into the landscape.

Thanks to the new lightweight construction, the material is not only extremely strong, but also much lighter than the steel currently used. At the same time, 90% less material is used, which reduces the weight significantly. This aspect will significantly simplify the construction of agrivoltaic installations in the future, as the installations will no longer need to be erected using heavy construction cranes. This, in turn, means that soil compaction during construction is almost negligible, and the use of machinery and personnel is reduced.

Markus Haastert, Managing Director of AgroSolar Europe, was particularly concerned about the use of organic materials in the agrivoltaic installations on the fields:

In the future, we can manufacture our agrivoltaic installations from exactly the materials that are grown under the installations! This means that resource consumption here has been maximally reduced, and AgroSolar Europe has succeeded in closing the material cycle. No waste materials are generated because, after 30 years, the installation can be dismantled, shredded, and used thermally.

Markus Haastert, CEO of AgroSolar Europe

This innovative development has another significant advantage that will revolutionize the construction method and also construction permits for agrivoltaics: Since the organic lightweight construction has tree-like structures, an increase in biodiversity in the area can be expected, as the spun flax structures provide ideal shelter for birds and insects and can be planted with climbing plants to blend even better into the surroundings.

Moreover, agricultural compensation measures, which are currently mandatory when using steel beams, might become reduced.

Due to the perfect landscape integration and the organic shapes of the new structures, acceptance by the public and decision-makers for agrivoltaics is likely to increase further. Already, the dual use through agricultural yields and energy production is a major bonus, and in the future, the sustainability of the installations will play a large role.

The materials used, such as flax or hemp, can be grown in Europe and Germany. This would eliminate the need for importing resources from overseas, making production more sustainable and cost-effective, and bringing value creation back to the domestic market. Markus Haastert says:

This brings the value creation back to Germany and reduces dependencies on other markets. That was our goal, and we are very proud of the result!

Markus Haastert, CEO of AgroSolar Europe

All these benefits will make building permits easier and further advance the expansion of renewables.